Dye Penetrant Inspection

for Metal Hose Assemblies

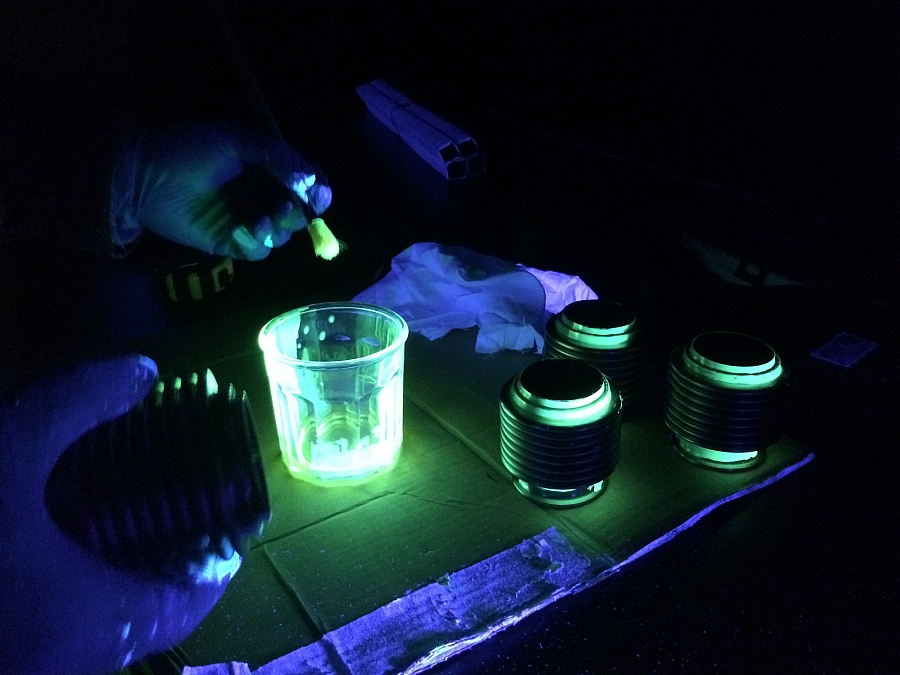

As well as producing a wide range of metal hose assemblies we also have state of the art testing facilities which enable us to test both our own products and third party parts. One of the most popular and most accurate types of testing is dye penetrant inspection. It used to detect surface breaks and faults in components, such as hairline cracks, surface porosity and lack of penetrantin welds. It can be performed on in service conditions to asses equipment on your site, or in our testing facilities dependant on your requirements. It is often used on metal hose installation, metal bellows, metal hose assemblies and expansion joints. Dye penetrant inspection has many advantages with it being cost effective and accurate. It is also non destructive, allowing the elements to be thoroughly tested without being damaged.

Experts in Dye Penetrant Testing Metal Hose Assemblies

All of our metal hose products are designed to the highest levels and are tested thoroughly before sale. If further assurance is required we can also facilitate additional non destructive testing to give peace of mind. All of our NDT team are fully qualified in the field and hold Level 2 in conformance to the American Society of Non-Destructive Testing Recommended Practice SNT-TC-1A, and this ensures that you receive the highest quality results. We also perform fluorescent and colour contract liquid penetrant flaw detection in house.

Find out more and about DPI & metal hose assemblies:

If you would like to learn more about our metal hose products, or our DPI testing then please get in touch with a member of our expert team who can answer any questions you may have. We work with many industries such as petrochemical, aerospace, government/military, cryogenic, power generation and many more; supplying a wide range of metal hoses and metal bellows which can be tailored to the specific needs of your business.